vickers hardness test experiment pdf|iso 6507 pdf free download : import The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess . webXvideos Br Apenas os melhores videos porno do xvideos brasileiros. Assistir videos de sexo grátis como o samba porno no xvideos brasil

{plog:ftitle_list}

Jogos Mortais X (2023) WEB-DL 720p e 1080p | 2160p 4K Dual Áudio 5.1 / Dublado 2023 1 h 58 min Assistir Online > Download Torrent > Dublados > HD 1080p > HD 4K > HD .

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess .vickers hardness test Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. (I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.

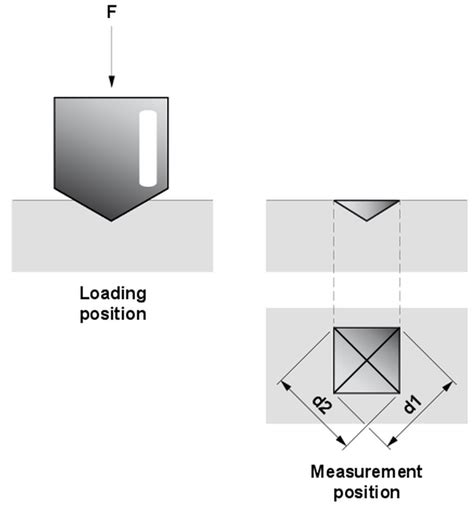

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees .Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of the .To study the Vickers hardness testing machine & perform the Vickers hardness test. 4. To study the Erichsen sheet metal testing machine & perform the Erichsen sheet metal test.The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees .

Static Indentation tests are based on the relation of indentation of the specimen by a penetrator under a given load. The relationship of total test force to the area or depth of indentation . Vickers hardness testing is one of the most useful methods to determine the hardness of materials. To calculate the hardness of materials, the key is to measure the diagonal length of the.ME 212 LABORATORY EXPERIMENT #3 HARDNESS TESTING AND AGE HARDENING 1. OBJECTIVE: Our primary aim is to measure the Rockwell Hardness values for different materials and estimate ultimate tensile strengths .At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness .

1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being expressed in the terms of load and area of the impression.

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surface

3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Vickers , Knoop and Brinell tests are determined after the test force has been removed. Thus the consequence of the elastic deformation occ urred during the test has been ignored. 2.1.1. The Vickers (HV) test was developed in England is 1925 and was formally known as the Diamond Pyramid Hardness (DPH) test.

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation.Meyer Hardness P πd = VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being

Objective a. To determine the indentation hardness of mild steel, brass, aluminum, and etc. using Vickers hardness testing machine. Introduction The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness test follows the brinell .

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely proportional to the hardness. . Repeat the experiment at other positions of the test piece. 9. Calculate the value of HB. V. OBSERVATIONS: Test Piece Material = Diameter of Ball ³D .Micro Vickers Hardness Tester Vickers Hardness Test of Curved Surfaces Vickers hardness is used as an index of the mechanical and physical properties of materials in a variety of fields, including quality control at production sites, research and development, and analysis. A distinctive feature of the Vickers hardness test is its simplicity.The document describes Experiment EL3-2 which is a Vickers hardness test. The experiment aims to determine the hardness of metals. Safety procedures are outlined including wearing protective equipment and knowing emergency .

computerised universal testing machine pdf

following are the most common hardness test methods used in today`s technology: 1. Rockwell Hardness test 2. Brinell Hardness 3. Vickers Hardness 4. Knoop Hardness 3.1: Rockwell Hardness Test The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied.1. To study the Brinell hardness testing machine & perform the Brinell hardness test. 2. To study the Rockwell hardness testing machine & perform the Rockwell hardness test. 3. To study the Vickers hardness testing machine & perform the Vickers hardness test. 4. To study the Erichsen sheet metal testing machine & perform the Erichsen sheet .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method. The main problem with hardness is that it’s not a well-defined property. The value obtained during testing of a given sample is different for different types of test, and also for the same test with different conditions. Identical hardness numbers can be obtained from materials exhibiting a wide range of yielding and work hardening . View Exp 2-BME 320-with Vickers test protocol.pdf from BME 200 at University of Victoria. Experiment 2: Density and Hardness of Ceramic Samples Karolina Papera Valente All students must take . 10 Experiment 2: Density and Hardness of Ceramic Samples Karolina Papera Valente All students must take “Workplace Hazardous Materials Information . The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all types of metals. The Vickers test is capable of testing soft and hard material. The disadvantage of this method is it takes time because the indentation must be measured under the microscope. Besides, the sample must .

This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force Ranges of test force, F N Hardness symbol Designation F W 49,03 W HV 5 Vickers hardness test 1,961 u F Low-force Vickers hardness test < 49,03 HV 0,2 to < HV 5higher. At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). N. oteThe Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

vickers hardness test procedure pdf

vickers hardness test manual

WEBMelhor visualizado em Google Chrome . Login: Senha

vickers hardness test experiment pdf|iso 6507 pdf free download